Cladding panels have skyrocketed in popularity in recent years due to its benefits, ranging from durability to affordability to cleanliness. Cladding panel materials can range from wood to PVC to fabric to lightweight concrete panels.

Interior concrete cladding might surprise you as a great panel material option. Below, we’ll outline the pros and cons of different materials and then showcase concrete cladding designs. When we’re done, you may set your eyes on a new material for your next project.

Things to Keep In Mind When Choosing Material for Your Interior Walls

When deciding on which material is right for your interior wall project, there are multiple things you need to consider.

- The cost of material and how it will impact your overall budget.

- Project timeline and which materials will add more time and labor (because that will add to your initial cost).

- How much customization you’d like to be able to accomplish.

- Ease of installation.

- Durability and longevity of the material.

- Aesthetic of the project.

- Availability of the material.

- Safety of the material.

Pros & Cons of Different Materials

Wood Finishes

Panels made of natural wood finishes are gorgeous and offer great thermal and acoustic insulation. They are pretty easy to repair and replace, and they can be sanded down, and a new sealant applied, to renew its appearance if it somehow becomes damaged.

The bad news is they are not waterproof or pest-resistant; they will rot if they come into any contact with water. Wood requires a lot of routine maintenance to maintain its aesthetic. If you use air-conditioning in your wood-paneled room, the wood will lose its natural moisture, and so you will have to apply a new seal frequently to keep it in good condition.

MDF

MDF, otherwise known as medium-density fiberboard, is a cheap, affordable option for wall paneling. If you stain it, you can get a natural wood-like look for a fraction of the price for actual wood. But compared to real wood, it is weak. It can crack or split when put under pressure, so you must be very careful while installing.

Installing MDF takes a large amount of time and effort compared to other materials, and it has to be done in the exact right way, or it will be incredibly aesthetically displeasing with a droopy section in the middle of the panels. Also, it requires a good amount of nails and sanding to give it a refined look.

PVC

PVC panels are suitable for a long-lasting, durable, fire-resistant, hygienic and easy maintenance material. They are often used in bathrooms and kitchens because they are waterproof. The installation is also quick and easy because the material is easy to cut.

The most significant disadvantage of using PVC is its chemical concerns. Chlorine is an essential component of PVC products, which is a volatile element and releases itself from PVC panels over time, leading to potential health concerns.

Gypsum

Gypsum boards are low-cost and have easy installation for flat, straight surfaces. They are fire-resistant and give customers decent sound control.

However, gypsum panels are challenging to install for curved surfaces and have very low durability. They are highly subject to damage from limited impact or abrasion, so it’s easy to dent or break during construction, leading to extra costs to replace the material and labor to reinstall it.

Fabric

Fabric allows you to explore your softer side. Fabric panels are ideal for projects with smooth, hard walls and can make a room feel more cozy and casual.

However, plain fabric walls aren’t great for acoustic insulation, so you should look for upholstered walls to give you a soft effect with the added plus of sound insulation. Unfortunately, this option can be expensive.

Why Lightweight Concrete Is the Best Solution for Your Space

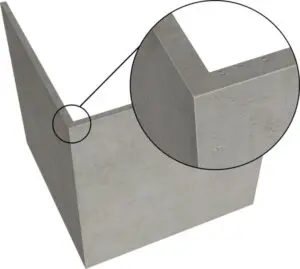

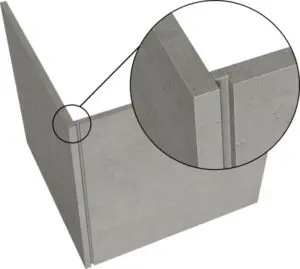

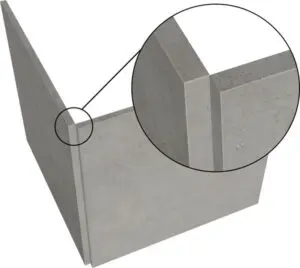

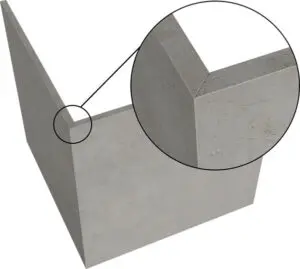

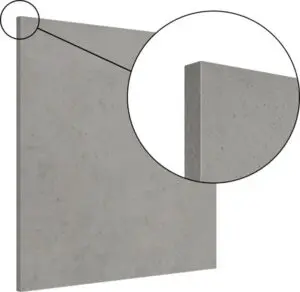

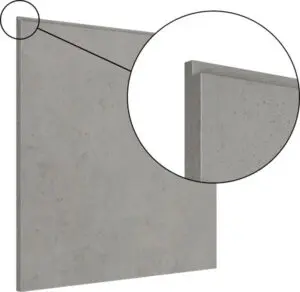

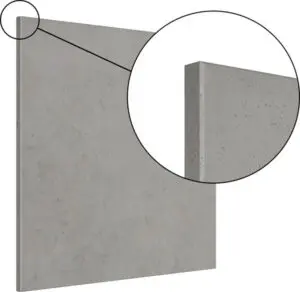

Lightweight concrete cladding is a standout when it comes to interior panel design. Cladding panels from Dekko are made from their proprietary lightweight concrete blend, giving you an authentic, industrial aesthetic. It is not faux concrete; it gives you the exact look and feel of concrete because that’s what it is. But it is ultra-light, weighing less than half the weight of regular concrete.

At only 3.5 pounds per square foot, Dekko’s concrete cladding panels don’t require foundation or structural modifications, meaning your installation can be done in a matter of minutes with just brad nails and foam adhesive. It almost sounds too good to be true — but it’s not.

Dekko ships all over North America and is a worldwide supplier. If you’re a large company looking to do a rollout of international stores with a matching aesthetic, Dekko will help you streamline your entire renovation project. Also, standard size panels are kept in stock for quick shipping and custom orders can be complete in just 4-6 weeks.

If your commercial space is high traffic, you don’t need to worry about wear-and-tear with Dekko. Dekko’s concrete is commercial grade and can handle the abuse of high traffic areas with low-maintenance to match because it is easily cleanable and repairable.

Lightweight concrete is also non-combustible to ensure it meets any commercial building regulators, making it a building material with safety top of mind. Dekko’s lightweight proprietary concrete blend won’t peel, flake or require sealant. In fact, it is one of the most durable materials in the construction industry.

It is also customizable. The options are endless, no matter if you’re looking for inset designs, curved panels, concrete logos, concrete retail fixtures or more. No matter what design you imagine, Dekko can make it happen.

Lightweight concrete is easily installable by general contractors and subcontractors. You don’t need to add time or extra labor to your project timeline by finding specialty trade installers. The material can also be cut on-site, saving you even more time and money.

Want to learn more about how lightweight concrete can help you achieve the project of your dreams? Check out wall cladding by Dekko today.

Comments are closed.